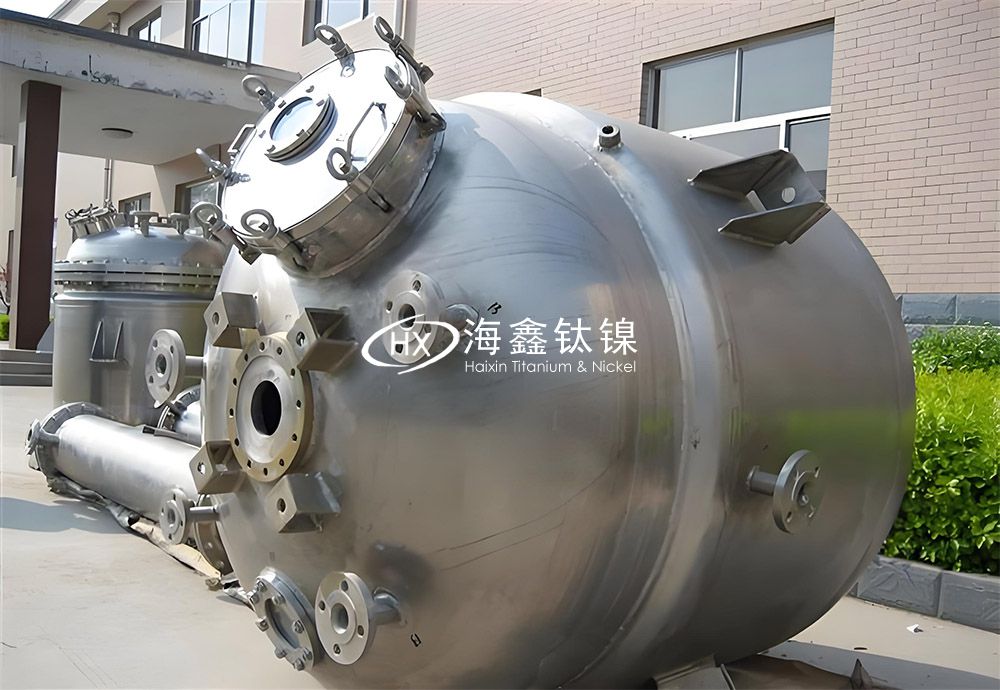

Titanium reactors offer advantages such as high-temperature resistance, corrosion resistance, non-magnetic properties, and non-toxicity. They ensure long service life, avoid contamination of reactants, and reduce economic losses and environmental impacts caused by maintenance and downtime.

Operating Procedures

1.Before Use:

Close the coolant inlet valve and drain residual coolant from the reactor and jacket.

Feed materials into the reactor, start the agitator, then open the steam valve and electric heating power.

After reaching the target temperature:

Turn off the steam valve and electric heating power first.

Shut down the agitator after 2–3 minutes.

2.After Use:

Drain residual condensate from the reactor and jacket.

Rinse thoroughly with warm water, followed by a 40–50°C alkaline solution for internal cleaning to enhance durability.

Never activate steam or electric heating when the reactor is empty.

Ensure steam pressure does not exceed the rated working pressure.

Common Operational Risks

1.Leakage:

During feeding under atmospheric pressure, failure to open the vent pipe may create internal pressure, causing pipe joint fractures and hazardous material leaks.

Discharging materials before cooling to the specified temperature risks thermal degradation, splashing, and operator burns.

2.Improper Feeding:

Rapid feeding, incorrect ratios, or disordered sequences can lead to localized overheating, rapid reactions, and hazardous gas release (e.g., explosions).

3.Overheating:

Rapid temperature rise with insufficient cooling or poor condensation may cause reactor rupture. Monitor temperature changes closely to prevent accidents.

Corrosion Effects on Titanium Equipment

1.Acids:

Titanium reactors resist most organic/inorganic acids and oxidizing-reducing acidic media.

2.Exceptions:

Hydrofluoric acid (HF): Highly corrosive.

Concentrated phosphoric acid (≥95%): Corrosive at temperatures up to 95°C.

3.Alkalis:

Alkaline media are more corrosive than acidic media.

Corrosion rate doubles for every 10°C increase in temperature.

Exercise extreme caution when handling hot alkaline solutions.

Key Notes

Follow strict operational protocols to ensure safety and longevity.

Regularly inspect seals, valves, and temperature control systems.

Avoid using titanium reactors with HF or hot concentrated alkalis unless specially treated.