With the enhancement of China's comprehensive national strength, the chemical industry has experienced rapid development, particularly in the chlor-alkali sector, where technological advancements have gradually improved. Titanium materials play a pivotal role in extending equipment lifespan, boosting production efficiency, and conserving energy within the chlor-alkali industry.

1. Advantages of Titanium Materials

The chlor-alkali industry involves highly corrosive media such as caustic soda, chlorine gas, and brine, which severely degrade pipelines and equipment, leading to premature failure and economic losses. Titanium and its alloys exhibit exceptional corrosion resistance, particularly in wet chlorine gas and sulfide environments. Despite higher initial costs, titanium equipment can extend service life by tens of times, significantly improving operational efficiency.

2. Applications in the Chlor-Alkali Industry

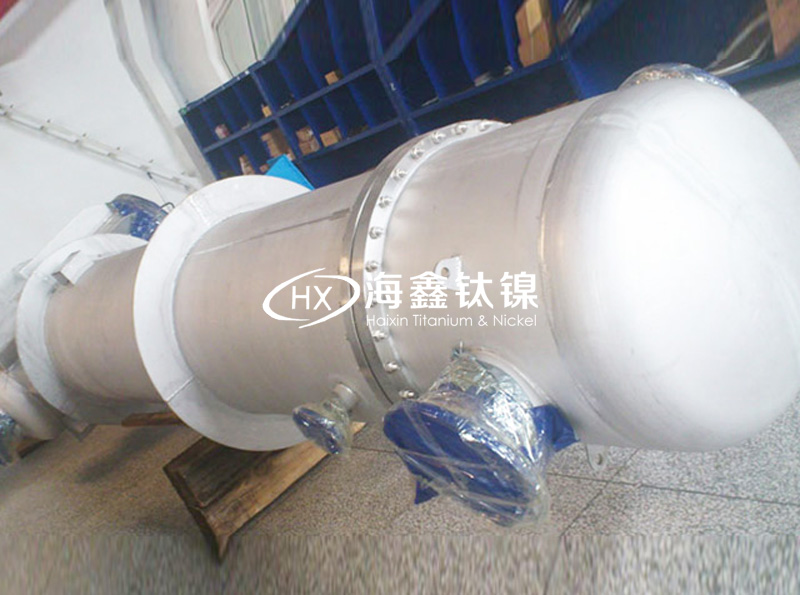

In civilian industries, the chemical sector was the earliest and largest adopter of titanium materials. Titanium is now widely used in caustic soda production, urea manufacturing, inorganic salts, and fertilizers. Among domestically produced titanium chemical equipment, heat exchangers account for the largest share of titanium usage, followed by titanium anodes and titanium vessels. Chlor-alkali products serve as foundational raw materials for pesticides, papermaking, and building materials industries, making chlor-alkali a critical development area in the chemical sector and the largest application system for titanium materials in China. The highly corrosive industrial media (e.g., sulfuric acid, hydrochloric acid, and caustic soda) used in chlor-alkali production demand stringent material selection to prevent leaks during actual production.

Conclusion

Titanium materials are increasingly utilized in the chlor-alkali industry. With continuous advancements in titanium alloy technology, existing challenges in titanium applications are being addressed and optimized. Titanium will play an even greater role in driving technological upgrades and equipment innovation within the chlor-alkali industry.